Taylor 49c BLACKFISH

Design # 133; Blackfish

Built by: Brooklin Boatyard

Launch: May, 2017

Jim Taylor 49 Blackfish sailing in the Eggemoggin Reach, Brooklin ME

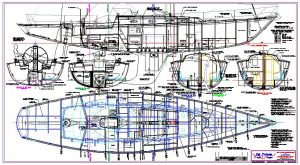

DESIGN #133: 49.0 ft LOA Cruiser/Racer: 2/22/17

Specifications:

LOA 49.0 ft Sail Area (RSAT w/genoa)1007 ft^2

LWL 35.0 ft ‘IM’ 53.0 ft

Max Beam 11.6 ft ‘J’ 15.6 ft

Draft 8.3 ft ‘LP’:142% (Genoa), 95% (Self-Tacker)

Disp (Meas Trim) 16,750 lbs ‘P’ 53.3 ft

Ballast 7,360 lbs ‘ E’ 19.4 ft

Equipment:

Spars: HallSpars; custom carbon mast (w/2 swept spreaders) & carbon boom

Rigging: Navtec; 22-13-5 Nitronic solid S.S. rod

Winches: Harken; 2×50.3.2STP primaries, 2×46.2 STP mainsheet, 2×46.2STP housetop (1 electric)

Electronics: B&G

Engine: Yanmar; 57 hp 4JH57 Diesel w/SD60 Saildrive

Design Comments:

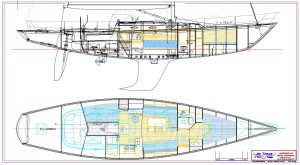

Blackfish is a variation on the Dreadnought (Design #132) theme. Dreadnought was also built by Brooklin Boatyard, and was launched in 2014. Lively performance, handsome aesthetics, a comfortable cockpit, and ample stability all remain priorities for Blackfish, her long, graceful overhangs, sweeping sheerline, and small counter stern all remain equally seductive, and the focus remains on contemporary performance, with hull, appendage, and rig detailing that is state of the art. The difference is that Blackfish will be raced more often, more aggressively, and in many more venues than Dreadnought, so in order to suit that ‘racier’ focus, her cabin house and interior are 2 feet shorter, her cockpit is shifted forward that same 2 feet, and her keel is 6 inches deeper. She will not often be taken offshore or on extended cruises, so her interior is focused on comfortable and attractive social spaces rather than on the cargo capacity required for passage making.

Blackfish is a variation on the Dreadnought (Design #132) theme. Dreadnought was also built by Brooklin Boatyard, and was launched in 2014. Lively performance, handsome aesthetics, a comfortable cockpit, and ample stability all remain priorities for Blackfish, her long, graceful overhangs, sweeping sheerline, and small counter stern all remain equally seductive, and the focus remains on contemporary performance, with hull, appendage, and rig detailing that is state of the art. The difference is that Blackfish will be raced more often, more aggressively, and in many more venues than Dreadnought, so in order to suit that ‘racier’ focus, her cabin house and interior are 2 feet shorter, her cockpit is shifted forward that same 2 feet, and her keel is 6 inches deeper. She will not often be taken offshore or on extended cruises, so her interior is focused on comfortable and attractive social spaces rather than on the cargo capacity required for passage making.

The hull and deck are constructed with the cold molded wood/epoxy technique for which Brooklin Boatyard is justifiably famous. The hull features tongue and groove Alaskan cedar planking each side of diagonal western red cedar veneers, and the deck boasts a handsome and traditional teak overlay. The stem, keelson, and ring frames are laminated Alaskan cedar. The keel loads are supported and distributed by a grid of laminated keel floors that are capped with unidirectional carbon fiber. Cold molded wood construction not only results in high strength and toughness relative to weight, but it also provides very impressive acoustic and thermal insulation. The interior is finished in a classic ‘Herreshoff’ style, with off-white painted surfaces trimmed with brightwork highlights that are a Brooklin Boatyard trademark.

Her light weight construction allows a high ballast/displacement ratio, which combined with a carbon rig, provides ample stability to support a generous sailplan. The boat will be day sailed and cruised with a lapper jib, but raced most often with a genoa. Asymmetrical spinnakers and modern, sophisticated deck hardware (including an electric main halyard winch) allow both racing and cruising crews to handle sails g with ease and confidence. Her electric drive jib furler and hydraulic backstay adjuster are both located below to keep the deck clear and the look clean. Her long ends give her generous deck area and gear locker volume.

Her light weight construction allows a high ballast/displacement ratio, which combined with a carbon rig, provides ample stability to support a generous sailplan. The boat will be day sailed and cruised with a lapper jib, but raced most often with a genoa. Asymmetrical spinnakers and modern, sophisticated deck hardware (including an electric main halyard winch) allow both racing and cruising crews to handle sails g with ease and confidence. Her electric drive jib furler and hydraulic backstay adjuster are both located below to keep the deck clear and the look clean. Her long ends give her generous deck area and gear locker volume.

Long sailing length and narrow beam will give this design a meter boat feel, with low drag and an especially comfortable motion in a seaway. Her low wetted area and large rig reflect her emphasis on rewarding performance in light-to-moderate air New England. Her deep, high aspect ratio appendages feature ample profile area to provide a user friendly ‘groove’ even when downspeed or in sloppy sea conditions. Her unusual combination of classic style with contemporary performance will set her apart from (and usually far ahead of!) everything else on the water.

Long sailing length and narrow beam will give this design a meter boat feel, with low drag and an especially comfortable motion in a seaway. Her low wetted area and large rig reflect her emphasis on rewarding performance in light-to-moderate air New England. Her deep, high aspect ratio appendages feature ample profile area to provide a user friendly ‘groove’ even when downspeed or in sloppy sea conditions. Her unusual combination of classic style with contemporary performance will set her apart from (and usually far ahead of!) everything else on the water.

Photo Gallery

Photos by BBY

Construction Gallery

- In the beginning, there was a keelson… Laminated Alaskan cedar, with extra width in way of the engine beds and strut drive unit and the rudder bearing.

- Keelson lowered into place over the internal structure. Many of the transverse molds set up for the hull planking remain with the hull as essential structure and joinery panels.

- The inside layer of tongue and groove Alaska cedar strip planking going into place.

- Off axis western red cedar veneers being vacuum bagged down to the strip planked inner layer.

- Hull removed from mold, moved outside, and rolled over. (Dreadnought photo)

- Interior structure; keelson, keel floors and inside skin. (Dreadnought photo)

- Unidrectional carbon capping vacuum bagged in place on top of keel floors. (Dreadnought photo)

- The construction approach relies on computer surface modeling and full size plotting. And lots and lots of clamps!

- The carefully shaped helm seat laminated and trimmed.

- Dreadnought out of the shed, ready for her Hallspars rig. Blackfin’s cabin house is shorter, her cockpit is shifted forward 2 feet, and her small jibs sheet to the deck instead of to a self-tacker track.

- Dreadnought on launch day. Blackfish is a near twin, but with different boottop and bottom colors.